X-Ray Reflectivity

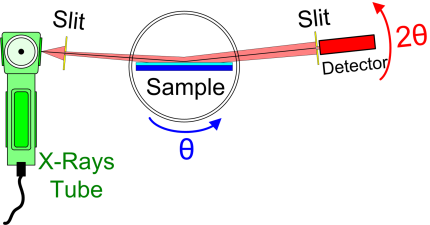

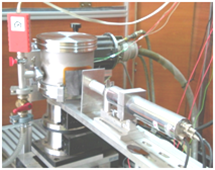

The installed experimental apparatus is essentially a custom-made horizontal X-ray reflectometer. The beam is obtained from a sealed Cu cathode tube (Philips PW 2253/20), which is supplied from a Philips PW 1130/00 generator. The goniometer is based on two high performance precision rotation stages (Newport) assembled one on top of the other, with their axis of rotation in accurate coincidence. The lower stage S1 bears the specimen holder on its axis, passing through the upper stage S2, which is also permanently attached on S1 and follows its rotation. The detector arm is attached on the upper stage S2 and is moving independently of the lower stage. In this way, the angle of incidence is adjusted by turning S1 to an angle θ from the incidence beam. Further turning of S2 by an equal angle θ brings the detector to 2θ angle from the incidence beam, securing the desired θ-2θ movement. Both rotators are controlled by a Newport MM4006 controller, which in turn is connected to the data acquisition computer running suitable acquisition and control software.

The accuracy in angle position for both rotators is 0.0010. A combination of divergence slits, receiving slits and soller slits placed in front of the tube and the detector is used for the conditioning of the X rays beam geometry. Nickel filters are used for the monochromatisation of the beam to CuKa wavelength. A scintillator detector (Canberra 1718) is used for the measurements of the reflected beam intensity through the acquisition software. Preliminary adjustments include the position of the samples surface parallel to the beam and accurate determination of the zero in scattering angle (detector in line with the incident beam). Further adjustment concerns the position of a knife-edge near the surface of the sample, in order to limit the illuminated area and increase the obtained resolution. This adjustment is carried out by utilizing a manual micro-positioning system, which allows for 3- axis accurate position of the knife-edge. The custom-made acquisition program, include suitable modules for the preliminary adjustments and display the measurements in real time, facilitating considerably the preliminary procedures.

Specifications of X-Ray reflectometer

Film thickness determination from 1 to 350 nm, accuracy better than 3%

Density determination with an accuracy of ± 0.03 g/cm3

Surface and interface roughness from 0 to 5 nm, accuracy better than ± 0.3 nm

Temperature-dependent measurements up to 500 °C

Automatic measurements over 7 magnitudes of intensity

Automatic data evaluation

Sample dimension down to 1cmx1cm

Equitant multilayer films

Density profile determination normal to the surface

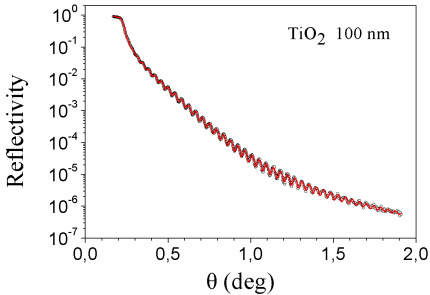

X-ray reflectivity spectrum of a TiO2 film. Due to the interference of waves, which are reflected from different interfaces within the system, intensity oscillations in the reflectivity can be observed. The periodicity in qz of these fringes can be related to the thickness d of the film via 2π/d.

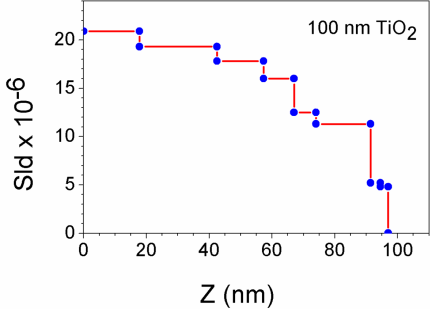

From the reflectivity profile, volume fraction profile of the non homogeneous TiO2 film deposited on a glass slab by the Langmuir Blodget method, can be obtained.